About Side Entry IML Solution

In Mold labelling system or IML is used for inserting the label inside the mold before the injection process and simultaneously to take out the final product after the molding for that piece is completed.

IML Robot is modular design and state of the art features it can produce lids, cups, buckets up to 20L and all kinds of other containers at a very high speed.

The Characteristic of Side Entry IML Solution

- Multi-functional: The structure design is good for the production of Lids, Cups, containers and Buckets up to 20L.

- Replenish the label without stopping the machine: With the Newly designed structure, it is possible to replenish the label with the machine running in the auto mode safely.

- Modular design: With modular design of the magazine and EOAT, it is convenient to change the products line by replacing the magazine and the EOAT sets.

We have provided our IML system for the following products:

- Ice cream containers

- Packed food containers

- Dry fruits and cookie containers

- Paint pail containers

- Oil and lubricant containers

- Butter and Dahi containers

- Cosmetic containers

- Serving trays and Anti Skid trays

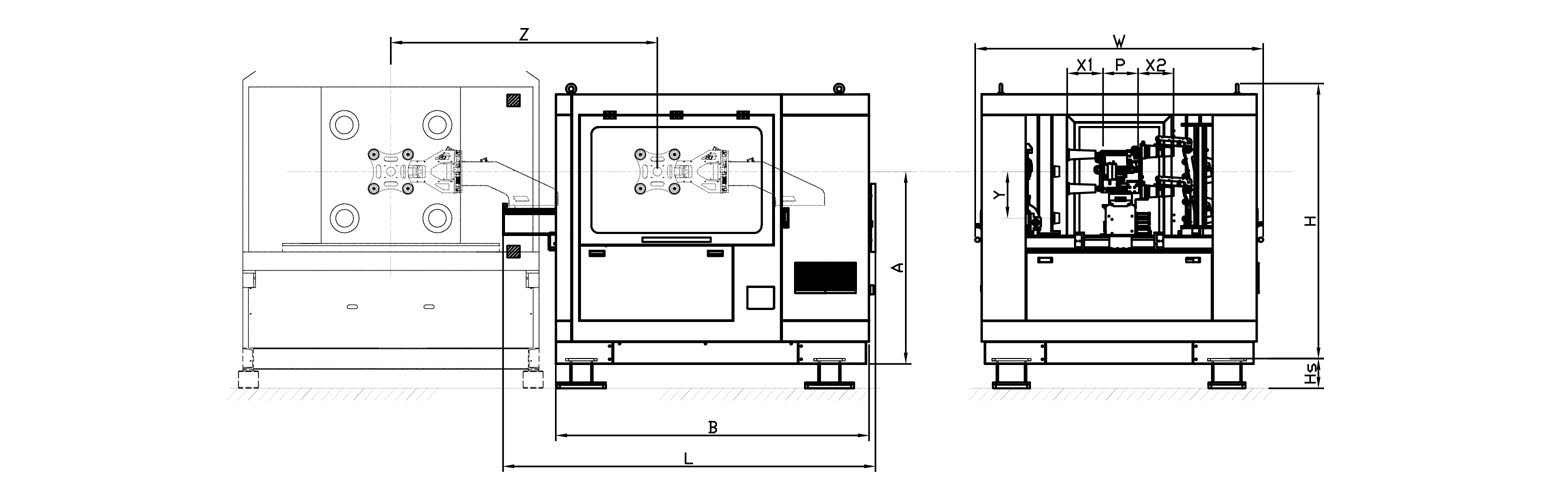

Standard layout

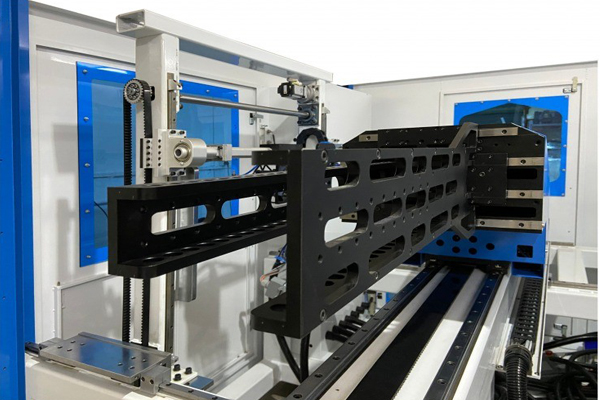

- Side Entry Robot

- Label cassette (Magazine)

- EOAT (End of Arm Tooling)

- Static charger

- Vacuum pump

Safety frame

- Stacking unit (Optional)